Why Galvo Solution Are Essential for Precision in Laser-Based Applications

Why Galvo Solution Are Essential for Precision in Laser-Based Applications

Blog Article

Discover the Crucial Uses Galvo in Modern Laser Technology

Galvo modern technology has arised as an essential element in the realm of modern-day laser applications, allowing impressive precision and rate throughout various markets. Its capability to manipulate lasers with fast-moving mirrors has actually transformed processes such as marking, inscribing, and cutting, while also making considerable strides in medical areas like laser surgical treatment and imaging. As sectors remain to advance, the potential for galvo systems to incorporate with emerging technologies raises essential inquiries regarding their future impact. What brand-new opportunities might unfold as these systems progress?

Overview of Galvo Technology

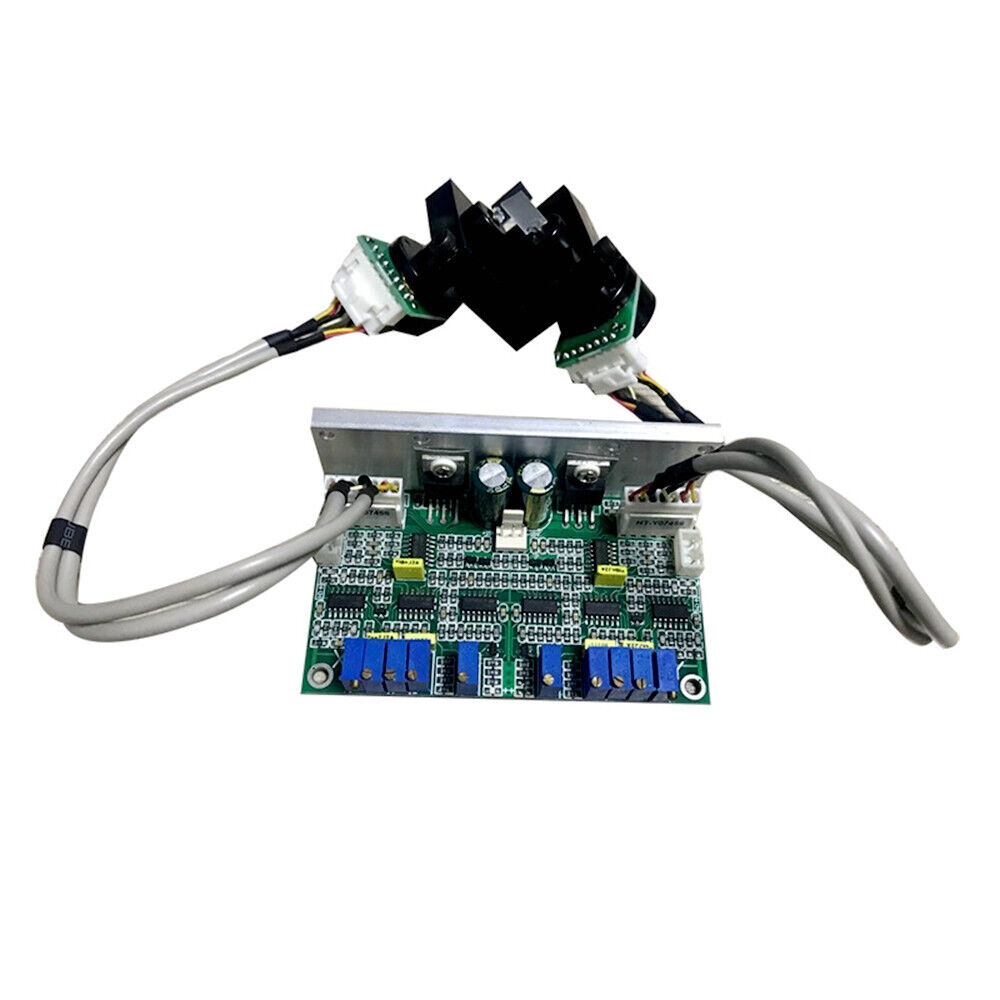

Galvo technology, or galvanometer modern technology, plays a critical duty in contemporary laser systems by enabling exact control of laser light beam placing and activity. At its core, galvo technology makes use of small, fast-moving mirrors that are activated by galvanometers. These mirrors are accountable for routing the laser beam to certain locations with high precision, enabling intricate patterns and designs to be created on different materials.

The fundamental parts of a galvo system consist of the galvanometer, control electronics, and the laser source. The galvanometers transform electrical signals right into angular movement, which equates right into exact and fast beam of light modifications. This capacity is essential for applications such as laser inscription, marking, and reducing, where precision is vital.

Industrial Applications

Along with noting, galvo modern technology plays a substantial role in laser cutting and welding applications. The capacity to manage the laser's centerpiece with high precision results in cleaner cuts and stronger welds, minimizing waste and enhancing product stability. Industries such as automotive and aerospace take advantage of these advancements, where accuracy is vital.

Additionally, galvo systems are employed in 3D laser scanning and additive manufacturing procedures. By swiftly adjusting the laser light beam's angle, they facilitate in-depth surface mapping and layer deposition, improving the effectiveness of manufacturing process.

Medical Uses

In the realm of medical technology, galvo systems have become an important tool for various applications, particularly in laser surgical procedure and diagnostics. Galvo Scanner. These systems help with specific beam guiding and fast movement, important for targeting cells with marginal invasiveness. In procedures such as laser-assisted cataract surgical treatment, galvo mirrors make it possible for the precise shipment of laser power, enhancing medical accuracy and lowering recuperation time for people

In addition, galvo systems play a significant function in dermatological treatments, including tattoo elimination and skin resurfacing. The capacity to regulate laser outcome dynamically permits specialists to personalize treatments according to specific skin kinds and problems, enhancing results while minimizing pain and adverse effects.

In the area of diagnostics, galvo technology is made use of in imaging systems, such as optical comprehensibility tomography (OCT) By making it possible for high-speed scanning of tissues, galvo mirrors improve the resolution and depth of imaging, crucial for very early detection of problems like glaucoma and retinal conditions.

Advantages of Galvo Equipments

Advanced light beam guiding technologies supply numerous advantages that enhance the capacities of laser systems across different applications. Galvo systems, specifically, are article source recognized for their exceptional rate and these details precision in guiding laser beam of lights, making them excellent for high-speed noting, engraving, and cutting tasks. Their quick action times allow for intricate layouts and intricate patterns to be implemented efficiently, significantly improving efficiency.

One of the key advantages of galvo systems is their capability to maintain light beam focus over a vast array of movement. This makes sure that the power supplied by the laser remains constant, leading to high-grade results with marginal distortion. Additionally, galvo systems require much less area compared to typical mechanical systems, as they use mirrors for beam direction, that makes them appropriate for small offices.

Galvo systems also improve operational flexibility. They can be easily incorporated with various laser types and control software, making it possible for personalization for particular applications. The decreased mechanical wear linked with galvo systems equates to lower upkeep expenses and longer operational life expectancies, making them a trustworthy selection for markets ranging from manufacturing to clinical applications. Generally, the benefits of galvo systems significantly add to the efficiency and efficiency of contemporary laser technologies.

Future Fads in Laser Modern Technology

Arising patterns in laser modern technology are poised to change different industries by enhancing capabilities and introducing brand-new applications. One substantial innovation is the integration of synthetic intelligence (AI) with laser systems. AI algorithms can enhance laser specifications in real time, boosting accuracy and efficiency in processes such as reducing, etching, and clinical treatments.

Furthermore, the miniaturization of laser gadgets is gaining traction. Compact, high-performance lasers are becoming progressively accessible, allowing their usage in portable tools for applications varying from medical diagnostics to mobile manufacturing options. This pattern improves flexibility and opens up brand-new markets for laser technology.

In addition, the growth of ultrafast lasers is accelerating developments in product handling and clinical therapies. These lasers, efficient in producing pulses in femtoseconds, permit for non-thermal and here are the findings exceptionally precise communications with materials, bring about improved end results in both commercial and medical care setups.

Final Thought

Finally, galvo modern technology works as a basic part in modern-day laser applications, enhancing precision and performance throughout numerous sectors. Its duty in industrial processes, such as noting and reducing, along with in clinical procedures, emphasizes its convenience and importance. The benefits used by galvo systems, including speed and precision, position them as important tools in advancing laser technology. Future patterns, especially the integration of AI and miniaturization, promise to more broaden their applications and impact.

Its capacity to control lasers with fast-moving mirrors has changed processes such as marking, inscribing, and cutting, while also making considerable strides in medical areas like laser surgical procedure and imaging.Galvo modern technology, or galvanometer technology, plays an essential role in modern laser systems by enabling specific control of laser beam of light positioning and motion. As laser modern technology proceeds to advancement, the function of galvo systems continues to be central, giving the required accuracy and effectiveness that modern-day applications demand.

Largely used in laser noting and engraving, galvo systems enable exact and rapid laser beam positioning, allowing for detailed styles on diverse materials such as steels, plastics, and glass.In the realm of clinical modern technology, galvo systems have actually arised as a vital tool for different applications, particularly in laser surgical treatment and diagnostics.

Report this page